Posted on 07/31/2010 12:51:20 PM PDT by Ernest_at_the_Beach

This post was up yesterday, but the discussion may have gotten confusing, because it was part of an open thread. I am putting the post back up, to facilitate discussion in a more organized manner. - Gail

Author's Note: Art Berman (aeberman) is an Oil Drum staff member and geological consultant whose specialties are subsurface petroleum geology, seismic interpretation, and database design and management. He has been interviewed on CNN and BNN about the Deepwater Horizon disaster. William Semple collaborated on this post. Mr. Semple is a drilling engineer and independent drilling consultant with 37 years of experience in the oil and gas industry. He worked for 16 years with a major oil company and has 24 years of experience as a drilling supervisor. He has been a guest contributor on The Oil Drum writing about the Deepwater Horizon (June 19, 2010).

A permanent solution to the BP Macondo blowout in the Gulf of Mexico may be achieved soon but there are risks. Admiral Thad Allen announced on Monday, July 26 that a static top kill would be attempted on August 2. The schedule may be accelerated to July 31 or August 1 according to an announcement today (July 29). The sealing cap has successfully stopped the flow of oil and gas from the well and the pressure continues to build slowly. Temperature at the wellhead has not increased, and seeps near the well are mostly nitrogen and biogenic methane unrelated to leakage. BP Senior Vice President Kent Wells’ technical update on July 21 explained these findings and showed how the well will be killed.

There are risks involved in both the top and bottom kill procedures. The purpose of this post is to describe those risks. There are two risks associated with the static top kill. First, it may not work at all and second, it may rupture the casing by pumping heavy mud under pressure (“bull heading”).

Kent Wells described the static top kill as a process of continuously pumping mud into the well until the oil is pushed into the reservoir. This is clearly erroneous and must be a simplification designed for the general public. What will more probably take place is a practice called “bleed and lubricate”. Heavy mud is pumped into the well through the choke and kill lines on the blowout preventer (BOP) and allowed to sink to the bottom of the well. Hopefully, the mud will retard the flow so that some of the pressure can be bled off by producing oil to the surface for a short period. Then, more heavy mud will be pumped into the well, and the process repeated as necessary until the well contains enough mud to kill the well.

The first problem with stopping the flow from the top is that it has to be an annular kill: the flow was coming up the annulus outside the production casing. This is a very narrow space so mud will have to pumped at high pressure to achieve entry. It will initially be working against a full column of gas and oil and the shut-in pressure at the well head. On the positive side, if produced sand has accumulated in the annulus, the operation may not have to contend with the full force of the reservoir pressure in addition to these obstacles. On the negative side, the well head seals might prevent or restrict downward flow, or the pumping pressure could rupture the 22-inch casing, or reach a pressure high enough to call off the operation.

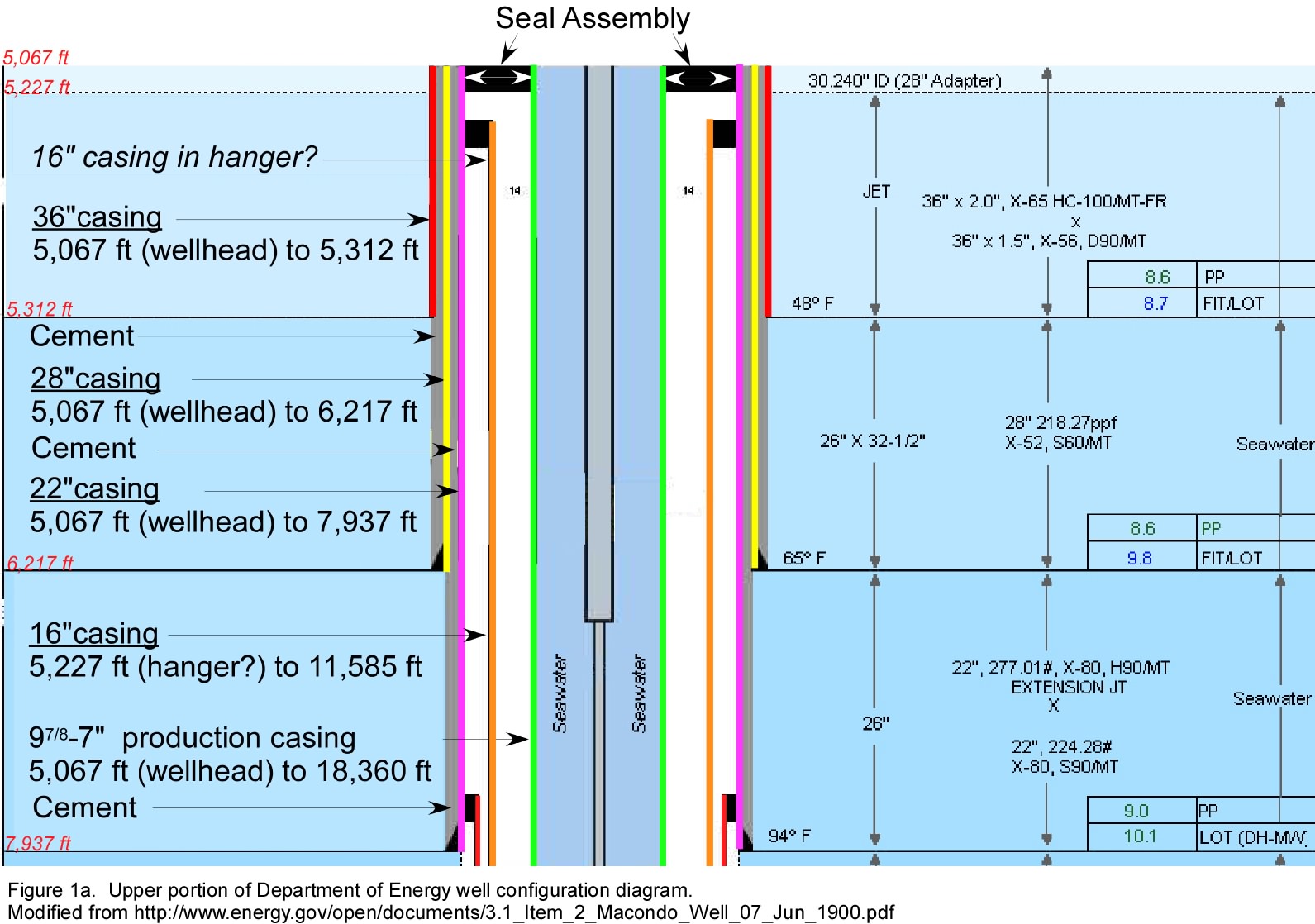

Figure 1a (based on a government document) shows that the upper part of the well bore is protected by three strings of casing (36-, 28-, and 22-inch) and cement down to 7,937 feet (measured depth below sea level). A fourth string of 16-inch casing extends nearly from the well head to where it is cemented at 11,585 feet, but it is apparently hung inside the 22-inch casing at 5,227 feet, leaving a gap of 160 feet. The 16-inch pipe has a burst rating approximately equal to the current shut-in pressure of 6,900 psi (80% of rating), but the 22-inch pipe does not meet this standard.

BP has said that the relief well DD3 plan will continue regardless of the success of the top kill operation. The main risk with a bottom kill is that it may take considerable time to accomplish. Because of the recent tropical storm, crews are just removing the storm packer today, and it will take time to re-enter and condition the hole before drilling resumes. BP estimate that the DD3 will intersect the Macondo well around August 10. Most efforts to intersect a blown-out wells require several attempts. The recent 2009 Montara blowout in the Timor Sea required four attempts that took a month after the relief well was near the blow out and cased. The bottom of the first Macondo relief well is currently located a few feet from the target at approximately 17,220 feet measured depth (based on Wells’ update and shown in Figure 1b).

The good news is that, in this case, the relief well does not, apparently, need to intersect the well exactly--it just needs to be close. Once the relief well penetrates the reservoir, enough mud can be pumped to hopefully overcome flowing pressure and kill the well. The bottom-kill option has the same annular flow path liabilities as the top kill, but it has the capacity to deliver higher flow rates directly to the reservoir. This approach will not cause significant pressuring near the well head and should not, therefore, pose a risk of rupturing the 22-inch casing.

The bottom kill option involves considerably less mechanical risk than the top kill, but time is the enemy, so the top kill makes sense. Maintaining the objectivity to abandon the operation rather than risk casing rupture will be critical.

Not sure but some of this discussion today may be new today.

Thanks for posting this EatB!

Wonder if this is where Simmons got some of his ideas.

My understanding is that the relief well intersects and cuts into the pipe, it doesn't go into the reservoir.

Can’t explain the difference ...i thought it was going to cut metal into the annulus....maybe I missed a plan change.

Cleaning the 3 Ram Stack Seal Leak (3 minutes)

3 Ram Stack Fast Leak Rate (35 seconds)

Thanks for ping.The big count down is on.

BP's Deepwater Oil Spill - Windows Can be Short, a Delay, and a Digression - and Open Thread

Might start with this subthread where Rockman addresses Allen's misstatement :

*************************************EXCERPT****************************************

At the end of the previous thread: Relief well collapses. The well bore did not collapse. Even in the captioned video they don’t say that. There was “debris” in the bottom 40’ of the hole. Debris is a very loaded word. It was sand and mud. When you POOH there is always a certain amount of “sloughing“ or as we call it “fill up“. It’s often caused by pulling the drill pipe out of the hole: it scrapes the sides and knocks some of the rock loose. The standard procedure when going back to bottom is to “ream” the last 100’ or so to clean out the fill. It wouldn't take the estimated 24 hours to just clean out the fill either. It’s also standard procedure to circulate the mud around a number of times to make sure it’s uniform and all the fill has been removed. The round trip time for mud at this depth would be around 6-8 hours.

A side educational note since we talking mud cleaning: As the mud gets back to the surface it passes thru the “shakers”: large vibrating horizontal screen panels that separate the cuttings from the mud. Typically one of the loudest spots on a rig. I’ve spent thousands of hours at the shaker watching returns. Double ear protection is highly recommended.

I still disagree with the technical point about top kill and pressure.

There is pressure in the well now, a static pressure because the well is sealed. It is about 7000 psi. That is the limit the resevoir is able to exert through the weight of the oil from 18,000 feet to 5000 feet. Someone has calculated what this puts the pressure at the resevoir to be, I can’t find it so lets just pick a number, like 12,000 psi (which would be true if the oil in the well weighed 5000 pounds per square inch of pipe diameter, I think).

If I now want to push mud into the static well at the top, I need only to exert slightly over 7000 psi at the connection, and mud will begin to flow into the pipe. Now, that mud will be heavier than the oil, and will begin to sink. Not very fast, but it will sink.

But the mud will also displace oil back into the resevoir. How? Because first, when I put mud into the pipe, since fluids are incompressable, oil must go out the bottom. And I can do that with about 7000 psi of pressure, because the mud that I trickle in is heavier than the oil I displace, which actually helps LOWER the pressure at the well head.

(I am ignoring the fact that there is gas in the line, and that gas is compressable; I ignore it because to the degree we simply compress the gas in the well, we also add a lot MORE weight to the stack, and lower the pressure at the top of the well by that much more).

After a short period of time, we can pump more mud into the top, because the pressure will drop. Or more likely, as we exert a constant pressure of 7000 psi, mud will flow faster and faster as the heavy mud displaces the oil back into the resevoir.

So I don’t see this as a big risk of blowout, nor do I see any reason there needs to be an oil flow to make it work.

Moreso, I don’t think the info on the casing pressure is valid. Because if the pressure is 7000 psi at the top of the well, and that is just at the max pressure for the casings, well the pressure is higher a thousand feet lower, and even higher as you move down more, and it’s the same casings.

July 31st 2010 8:22 PM PST Skandi 2

Old BOP Seal Leak Side 1 (16 seconds)

July 31st 2010 8:24 PM PST Skandi 2

Old BOP Seal Leak Side 2 (26 seconds)

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.