Posted on 05/19/2014 12:46:57 PM PDT by nickcarraway

Scientists at MIT are using a new technique that could print responsive objects—from water pipes to sneakers—that adapt to their surroundings on their own.

These days, 3D printing seems to be at the core of most new new research ventures, whether it's developing ways to print entire meals or recreating facial features to repair a patient's face.

But Skylar Tibbits wants to up the ante: He's hoping 4D printing will be the thing of the not-so-far future.

The name for his concept, Tibbits admits, was a bit lighthearted at first. At the Massachusetts Institute of Technology, Tibbits and researchers from the firms Stratasys and Autodesk Inc were trying to come up with a way of describing the objects they were creating on 3D printers—objects that not only could be printed, but thanks to geometric code, could also later change shape and transform on their own.

The name stuck, and now the process they developed—which turns code into "smart objects" that can self-assemble or change shape when confronted with a change in its environment—could very well pop up in a number of industries, from construction to athletic wear.

“Normally, we print things and we think they’re done,” Tibbits says. “That the final output and then we assemble them. But we want them to be able to transform and change shape over time. And we want them to assemble themselves.”

Tibbits, a research scientist at MIT, was given the go-ahead last year to establish what’s known as the university's Self-Assembly Lab. The challenge was to see how smart researchers could make an object without relying on sensors or chips; how fluid they could make something without wires or motors.

As luck would have it, when Tibbits shared this dilemma with acquaintances at Stratasys, a leading 3D printing firm, they told him the company had developed a printing material that expands by 150 percent when placed in water. It sounded promising. But the real question was how to bring precision to that transformation so an object could unfold, curl and form specific angles instead of just swelling up like a bloated sponge.

Tibbits’ answer: Geometry.

With a 3D printer, an operator plugs in a virtual blueprint for an object, which the printer uses to construct the final product layer by layer. To make something "4D," though, Tibbits feeds the printer a precise geometric code based on the object's own angles and dimensions but also measurements that dictate how it should change shape when confronted with outside forces such as water, movement or a change in temperature.

In short, the code sets the direction, the number of times and the angles at which a material can bend and curl. When that object is confronted with a change in environment, it can be stimulated to change shape. Pipes, for instance, could programmed to expand or shrink to help move water; bricks could shift to accommodate more or less stress on a given wall.

Tibbits demonstrated the concept of 4D printing at a TED talk last year, during which he showed how a single strand of printed material could be programmed to fold, on its own, into the word “MIT.”

(See a video of that demo below)

The shapes of things to come

At face value, it's a concept that's very cool. But when can we expect to see these kinds of transformations out in the real world?

In some cases, they're already happening. Tibbits points out that in nanotechnology, scientists have been able to program physical and biological materials to change their shapes and properties—such as using DNA to self-assemble nanorobots.

Making this happen on a human scale, he concedes, is much more challenging, particularly in more traditional industries, such as construction. But Tibbits says at least one company is interested is seeing how 4D programming can be applied to infrastructure. There's potential, he says, in using self-assembling materials in disaster areas or extreme environments where conventional construction is not feasible or too expensive. For instance, he sees a future for what he calls “adaptive infrastructure” in space.

Tibbits say his lab is working closely with a number of industry partners on ways they could incorporate the 4D concept into their businesses. As for where we might see transforming products on the shelves, Tibbits envisions innovation in furniture or sportswear. He offers the example of sneakers that could change shape and function in response to how they're being used.

“If I start running,” he said, "[the sneakers] should adapt to being running shoes. If I play basketball, they adapt to support my ankles more. If I go on grass, they should grow cleats or become waterproof if it’s raining. It’s not like the shoe would understand that you’re playing basketball, of course, but it can tell what kind of energy or what type of forces are being applied by your foot. It could transform based on pressure. Or it could be moisture or temperature change. “

Multi-dimensional thinking

Here’s some other recent developments in 3D and 4D printing:

Army maneuvers: The U.S. Army has given a grant to Harvard University, University of Pittsburgh and University of Illinois to explore ways the military could use self-assembling objects, raising the possibility of shelters or bridges that spring into shape.

Just don't tell anyone your makeup came right off the printer: Harvard student Grace Choi has created a prototype for a 3D printer called "Mink" that is designed to let users choose any color imaginable and then actually print out makeup in that hue.

All in a day's work: In China, an engineering company used 3D printers to build 10 one-story houses in a day. The printers, which were 33 feet wide and 22 feet high, used a mix of cement and construction waste to build the walls layer by layer.

And for more on the potential of 4D printing, check out this video:

Anyone who read science fiction back in the 1960s knows that the 4th dimension is time. Unless the produced objects enable time travel, they cannot be described as 4D.

Some day her prints will come…

Kind of like the jacket in “Back to the Future” that drys itself when wet.

no matter how hard I try, I can’t really imagine what a 4D object would look like.

I can imagine a 38DD.......................

These "4D" objects change across time.

If only Escher had had this technology to play with.

Maybe the printer has a timer on it.

/johnny

They do travel in time. Forward. Like the rest of us. ;-)

“Anyone who read science fiction back in the 1960s knows that the 4th dimension is time. Unless the produced objects enable time travel, they cannot be described as 4D.”

Only SF writers who don’t know anything about science. They should have read Flatland instead of A Wrinkle in Time.

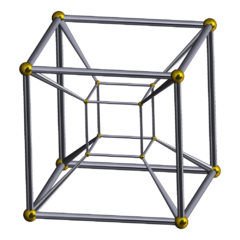

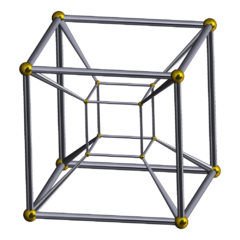

We live in 3 spatial dimensions and 1 temporal dimension. A 4th spatial dimension would add another set of points (W,X,Y,Z) like the tesseract displayed earlier in the thread.

I see 3-D printing as just one small area in the ever expanding world of technology. A lathe was needed to make the printer nozzle. Microcode and computers on a chip to control it. Hobbyist and robotics fan-boy websites, as well as thousands of youtube videos reveal amazing things people do in their garages and dens. 3-D printing is sort of an adjustable wrench in the larger scheme, as amazing as the milling machine or silicon lithography when they first came out.

Printer nozzles can be printed. Just like I can build another lathe with my existing lathe. But you have to have the first one.

/johnny

It prints in the past?

i thought 4 d was the power for one solid object to pass thru another.

Pshaw. I’m waiting for the 5-D printer to come out.

ha! comment of the day!

Dumb science journalism. It’s a shape-changing (bendable) 3d object.

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.