I came across a good overview that better explains the why to your question from yesterday. I suspect you were only thinking of the separation portion. This is probably more than you wanted to know.

All refineries perform three basic steps:

Separation

Conversion

Treatment

http://www.eia.gov/energyexplained/index.cfm?page=oil_refining#tab2

Separation

Heavy petroleum components or fractions are on the bottom; light fractions are on the top. This difference in weights allows for the separation of the various petrochemicals. Modern separation involves piping oil through hot furnaces. The resulting liquids and vapors are discharged into distillation units.

Inside the distillation units, the liquids and vapors separate into fractions according to their weight and boiling point.

The lightest fractions, including gasoline and liquid petroleum gas (LPG), vaporize and rise to the top of the tower, where they condense back to liquids.

Medium weight liquids, including kerosene and diesel oil distillates, stay in the middle of the tower.

Heavier liquids, called gas oils, separate lower down, while the heaviest fractions with the highest boiling points settle at the bottom of the tower.

Conversion

Cracking and rearranging molecules takes a heavy, low-valued feedstock and changes it into a lighter, higher-valued output such as gasoline. This is where fractions from the distillation units are transformed into streams (intermediate components) that eventually become finished products.

The most widely used conversion method is called cracking because it uses heat and pressure to crack heavy hydrocarbon molecules into lighter ones. A cracking unit consists of one or more tall, thick-walled, bullet-shaped reactors and a network of furnaces, heat exchangers, and other vessels.

Cracking is not the only form of crude oil conversion. Other refinery processes rearrange molecules to add value rather than splitting molecules.

Alkylation, for example, makes gasoline components by combining some of the gaseous byproducts of cracking. The process, which essentially is cracking in reverse, takes place in a series of large, horizontal vessels and tall, skinny towers.

Reforming uses heat, moderate pressure, and catalysts to turn naphtha, a light, relatively low-value fraction, into high-octane gasoline components.

Treatment

The finishing touches occur during the final treatment. To make gasoline, refinery technicians carefully combine a variety of streams from the processing units. Octane level, vapor pressure ratings, and other special considerations, determine the blend.

It is the reason the simplified flow diagram of a refinery looks like:

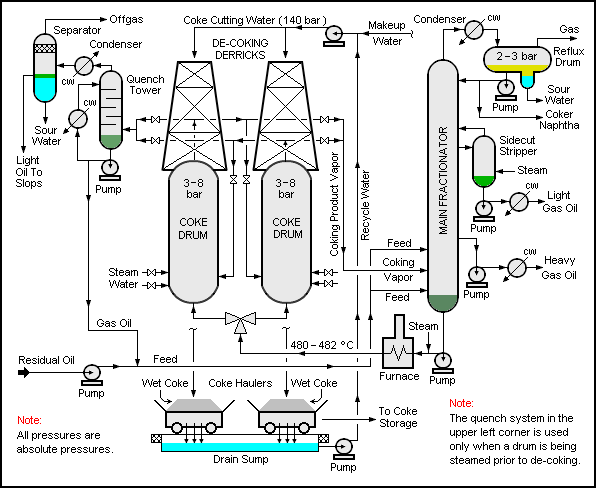

Keep in mind each one of those boxes above represents many different pieces equipment used together in a process unit. For example:

Fluid Catalytic Cracking unit

Delayed coker