Skip to comments.

The World’s First Clean Oil Sands Project: An Interview With Dr. Gerald Bailey

Oilprice.com ^

| 09-01-2015

| sjiek

Posted on 09/01/2015 9:29:52 AM PDT by bananaman22

fter decades of exhaustive attempts to overcome the dirty reputation of oil sands, we finally have an environmentally-friendly and low cost method to tap into these vast resources in the state of Utah—good news both for Mother Nature and all oil and gas investors.

MCW Energy Group’s CEO, former Exxon President of the Arabian Gulf region, Dr. R. Gerald Bailey, tells Oilprice.com in an exclusive interview that his hunt for an innovative technology that simultaneously makes money and cleans up the environment is over. The race to capitalize on Utah’s vast oil sands resources is on, and only the ‘clean’—both financially and environmentally—will survive.

Coming hot off of the successful launch of clean oil sands operations in Utah, while other oil sands projects are under fire from protesters

(Excerpt) Read more at oilprice.com ...

TOPICS: Business/Economy; Science

KEYWORDS: antifracking; energy; environment; epa; fracking; globalwarminghoax; methane; oil; oilsands; opec; petroleum; popefrancis; putinsbuttboys; romancatholicism; russianstooges; tarsands; utah

To: bananaman22

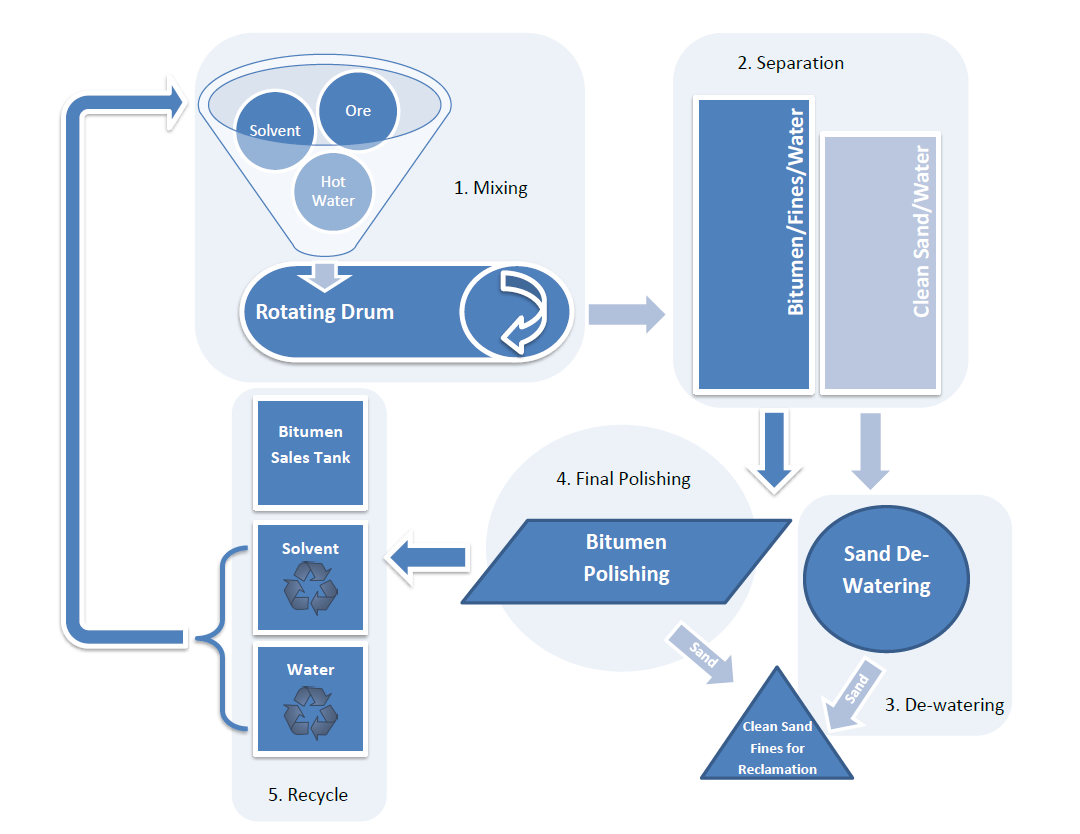

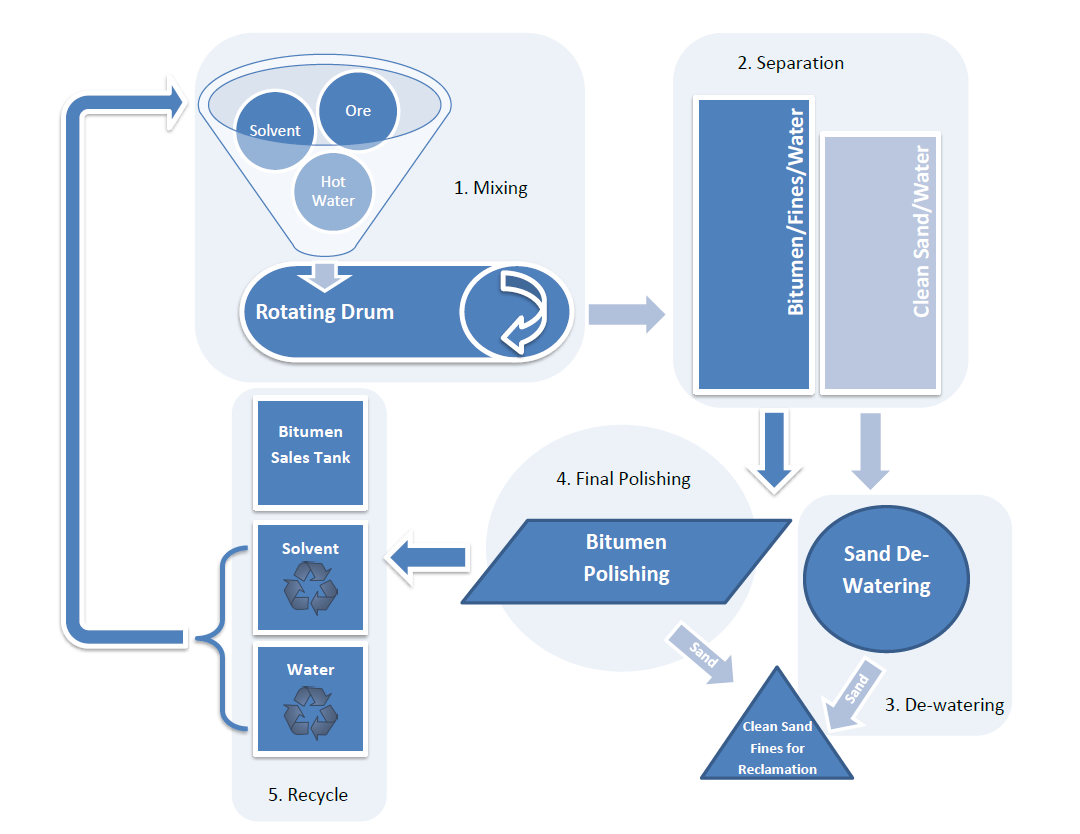

http://www.usoilsandsinc.com/index.php/operations/extraction-process US Oil Sands’ proprietary extraction process uniquely engages the use of a biodegradable, non-toxic solvent derived from citrus products. The result is that:

Only very low mechanical energy is required to mix the oil sands, water and solvent.

Elimination of the activation of the fine clay particles and resultant creation of the emulsion of water, clay and bitumen.

Reduction of suspended clay particles within the process water which eliminates the generation of liquid tailings

Elimination of middlings. Clean solids, water and bitumen phase separation do not require tailings ponds to settle a middlings phase.

All of the capital cost and operating expense associated with creating bitumen froth, froth treatment, middlings treatment and tailings pond management and reclamation is eliminated. The result is a highly capital efficient and operationally simple extraction process.

The process is outlined here:

2

posted on

09/01/2015 9:32:50 AM PDT

by

thackney

(life is fragile, handle with prayer)

Disclaimer:

Opinions posted on Free Republic are those of the individual

posters and do not necessarily represent the opinion of Free Republic or its

management. All materials posted herein are protected by copyright law and the

exemption for fair use of copyrighted works.

FreeRepublic.com is powered by software copyright 2000-2008 John Robinson