“... it seems to me a 3-d print of these things on most widely available printers would be more danger to the user than to anyone else, if actually fired...” [OldNewYork, post 18]

Not if the parts are designed properly.

It’s been proven that barrels, breeches, even springs can be made from relatively soft materials (some plastics) that will withstand a few firings from moderate-pressure pistol cartridges like 9mm NATO (rifle rounds, which create pressures twice as high, are another story).

It’s unlikely that any additive manufacturing process will provide one-for-one replacements for parts that are currently fashioned from steel or aluminum, so we’re not going to see anything like an all-3D Glock 17 nor Colt’s AR-15.

Any 3D-printed gun will not be the match of a more conventionally manufactured firearm in size, weight, durability, accuracy, nor handling qualities.

Making it go bang once isn’t the problem; making it do so, over and over, without fail, for a useful length of time is.

Even when guns are made of steel and aluminum, shaping the part isn’t the limitation; heat treatment, tempering, hardening are. One cannot simply forge (nor machine, nor cast) a barrel out of, say, steel and have it work. It must be tempered and often surface hardened: sometimes in a number of different ways, in the proper sequence too.

Springs are the worst: one must coil a spring first, out of soft material. Only then can it be heat-treated (tempered) to bring out its elasticity. It can be done theoretically with a backyard furnace, but getting the right temperature and duration can require some skill, and (given certain parts shapes) cannot be done without modern instruments and heat sources, typically available only to heavy industry.

Making springs is nowhere near as difficult as you think.

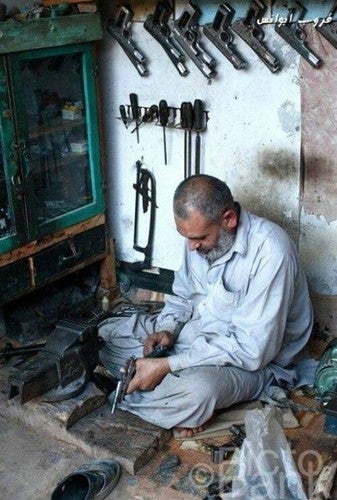

It is a common problem for gunsmiths.

Additionally there are numerous ready made coil springs easily purchased on the market.

Springmaking without Tears