Posted on 08/08/2019 9:38:43 AM PDT by amorphous

I’ve got them all on DVD. Just wish Groening was still making more episodes.

1. It will get you pinged to any article that strikes my fancy.

2. The wagon wheel, two ways, a) There are removable supports, either snapped off after the print is done, or washed away in a suitable solvent, often nothing more than water. b) You could print the wheel in two horizontal halves, and glue, melt, snap or pin them together after printing.

Bah! 3-D printed coffee tastes like burnt plastic, or Starbucks...

Welcome aboard, all y’all!

You’re absolutely correct about the much lower costs, but I have a need for the moving parts to be enclosed. I have everything from welders, grinders, saws, etc., in one shop. I even made a cover for the XYZ Pro. And the QIDI Tech X-Max is filtered, so that’s another thing I like about this particular model. And the filament can be kept inside its enclose as well.

That said, there are applications were only nylon will suffice, such as for use as a bearing/bushing, flexibility and strength for hinges, excellent layer adhesion, and so forth.

If you have moving parts on your models, nylon bushings or hinges made from nylon would be the way to go. Also, things like propellers, which might be subject to blades getting broken off, would be another great application.

I started out working with ABS. It has it's own set of characteristics which drive what its used for. However, have you tried the newer PLAs? They are easier to print at lower temps and can be more readily sanded and painted. I use PLA in making models for castings, and etc.

Excellent suggestion. They could also be riveted or fastened using sheet metal screws or nut and bolt fasteners. I pop-rivet the stronger plastics, like nylon, PETG, and sometimes ABS often. Just use a backing washer to prevent pull-though.

Thanks to all the responders about the wagon wheel shape. So, sacrificial material is laid down first, that’s clever. You mention that a “slicing app” will add the support for me. I take this to mean the 3D design software where the print design is created? That actually brings me to my next question. You have to have some pretty solid 3d design skills to make that adapter, to get those threads modeled correctly, etc. What 3d modeling program should I start with if I wanted to make a printable model? Freeware is always nice to learn on.

Actually it's the 'slicer software' which will add support structure if you tell it to. I usually design my own supports into the object I'm creating because the 'slicer software' tends to overdo it.

Btw, many thousands of items have already been created by others. Do a search on a site called https://www.thingiverse.com/ and download the .stl file of your choice. The slicing software usually comes with your printer and open source versions are available. The 'slicing' software creates a .gcode file which the printer uses to print the item.

There are several free 3d design software packages you can use; 123D Design, Fusion 360, SketchUp, and etc. Check out https://www.tinkercad.com/ for a simple, easy to use online 3d cad designer which has tutorials to get you quickly creating 3d designs. The Tinkercad site also has many 3d files for download, created by others. The other applications all have tutorial videos available on Youtube.

I wrote a lot of VRML back when it was a thing.

Sorta miss it.

Thanks for the suggestions. Now I need to figure out which 3D printer to buy.

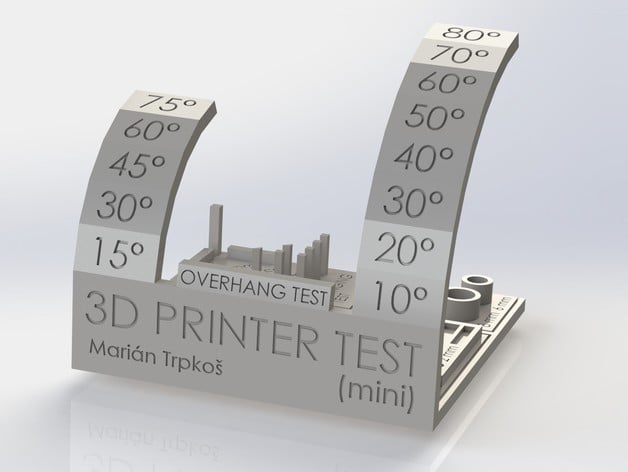

Nice adapter for the shop vac. When I see this image, a couple questions come to mind. Number one, did you create this 3D image from default shapes within the software, which you combined and skewed to fit your purposes? Secondly, you see that second portion of the shape (counting from the bottom), the part that necks down? That angle of reduction appears to be maybe 30 degrees. My question is, what is the maximum angle of reduction that would successfully 3D print? It seems to me that you really couldn’t exceed a 45 degree reduction. If you sketched out a shape that cannot be printed, say it necks down at a 60 degree angle, would the software warn you? I’m just wondering how smart the software is in terms of determining if an “illegal” shape has been created that would require some kind of support.

Building your own 3d printer and messing around with its code might be something of interest to you then?

You're in luck, as they've dropped a lot in price from when they first hit the market. And there are now a lot of options and choices in printers.

I currently use the XYZ Pro because it allows for third party filaments, is enclosed, comes with a workable slicing app, is wireless, and priced right.

Yep. Most design apps allow for precise control down to a fraction of a mm or thousands of an inch from basic shapes, and some complex shapes/objects like machine thread generators. You build the object from numerous shapes. The vac adapter was built from only 4 shapes (IIRC) in just a few minutes, mostly spent measuring dimensions.

Once you get a shape, you can copy/paste and cut off portions you want to use/lose. It's pretty fun and actually kind of fast compared to how things were done in the past. It's also fairly intuitive. You can take it as far as you want. Even to code your own shape generators if you want.

My question is, what is the maximum angle of reduction that would successfully 3D print?

A better term might be angle to horizontal. The printer has to have something to lay the next layer of filament on, but it can cross a span of a certain length depending upon a number of factors. Likewise, it can print a cantilever out past an edge to a certain distance. This is why it's able to print something with what you refer to as 'angle of reduction'. As a guess, a 3d printer can probably build a shape with less than 3-5 degrees of angle from its horizontal print bed, without any support - depending upon a number of factors, of course.

Today's slicing software will warn you of certain issues. Usually a warning, "Their is something wrong with the model, do you want to correct it". If you answer yes, it seals of a opening or something you didn't want. So it needs a lot of work, at least the less expensive software I've only had an opportunity to work with. Simply 3D simulates the build allowing you to find and fix problems layer by layer.

Simplify 3D does do a fair job of placing supporting structures where they need to be, and it offers you quite a bit of control in doing so. I just like placing them myself.

If you enjoy figuring things out, and sounds like you do, then 3D printing is for you! ;)

Btw, I forgot to mention that I had made a trip to the big box hardware store looking for an adapter - with no luck. IMO, a 3D printer is a must have for a DIY'er or prepper. Certainly so for inventors and tinkerers.

Why didn't I just print it to begin with? It's one of those things you think must be a standard accessory, readily available for just a few bucks at the nearest big box or online.

Apparently the technical term is, "degree of overhang". And it seems 80 deg is about the limit, though I'm pretty sure I've tweaked the angle to single digits looking at it from the printer base ( > 80 degrees from the "degree of overhang" perspective, 90 degrees being parallel to the base ).

No, just musing ...

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.